Biomimicry is the concept of producing technologies that emulate nature’s own innovations.

Ever since the publication of the book ‘Biomimicry: Innovation inspired by nature’ by Janine M. Benyus in 1997, there has been a surge in the amount of research conducted in this revolutionary new science. However, the concept of biomimicry is not really a ‘new’ phenomenon, coined by Otto Schmitt in the 1950’s.

One classic example of biomimicry is Velcro, which was inspired by the hooks of burr spines. Below are some more examples of technologies motivated by nature. If you find them as interesting as I do, consider reading Janine Benyus’s book, this paper titled ‘Tapping into Nature’ and take a gander at AskNature’s website.

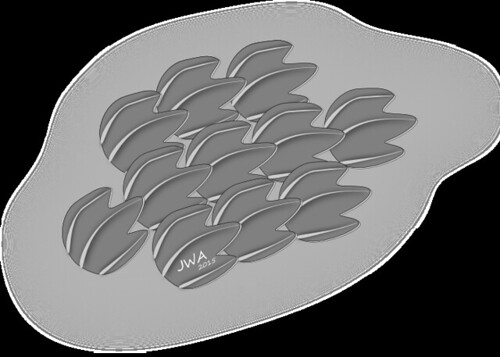

Sharks are one of the only ocean dwellers that don’t collect algae and barnacle growth.

This is because the microscopic ‘teeth’, otherwise known

as dermal denticles, that form shark skin is grooved. This topography of the denticles makes it harder for bacteria

to attach to the shark.

Sharklet Technologies have

successfully replicated the microscopic diamond pattern of denticles. By applying this to materials the

occurance of bacterial growth can be significantly reduced [1].

This has a broad range of applications including medical equipment, clothing and boat surfaces.

You may have also heard about the denticles providing improved

hydrodynamics, helping sharks speed through the oceanic highways.

This inspired designs for swim wear, with claims that the new material increases swimming speeds.

However, this claim was later retracted with evidence showing that, although the denticles on

shark skin can increase swimming speeds by 12.3%, the bio-mimicked material had no such effect [2].

1. Mann et al. 2014. Surface micropattern limits bacterial contamination. Antimicrobial Resistance and Infection Control. 3:28.

2. Oeffner and Lauder. 2012. The hydrodynamic function of shark skin and two biomimetic applications. J. Exp. Biol. 215, 785–795. (doi:10.1242/jeb.063040)

Without limbs the body of a snake has substantial contact with the ground. The snake requires its skin

to be tough in order to endure abrasions, all the while maintaining high flexibility for

locomotion. Snake skin successfully does this through multiple skin layers and regularity in scale patterning

and form.

Observations of Ball Python (Python regius) skin reveals tightly aligned hexagonal scales [1].

Parker Hannifin is a company which specialises in hydraulic hoses; inspired by snake skin they

manufactured a heavy duty hose called the ‘Cergom Hose’. By emulating the hexagonal cell structure

of snake skin the company was able to produce an armoured, yet flexible hose that can transport abrasive

materials with minimal damage. This is particularly helpful for industrial businesses such as steelworks,

cement works and power plants.

1. Abdel-Aal, H.A. and Mansori, M. El. 2011. Python Regius (Ball Python) shed skin: Biomimetic

analogue for function-targeted design of tribo-surfaces. In: Biomimetics – Materials, Structures

and Processes, pp. 127–148.(doi:10.1007/978-3-642-119347)

Any insect that messes with a bombardier beetle (Carabidae) is in for a world of pain. If aggravated,

the beetle can spray boiling liquid from its abdomen. With a range of 10x its body length,

there is no escape!

The bombardier beetle is a specialist sprayer which inspired a system called

µMist. µMist

is currently developed for the automotive industry, providing a novel fuel injection system [1].

However the technology can also be modified for application in industries concerning food,

drug delivery and fire protection.

1. N. Beheshti et al., “µMist®-The next generation fuel injection system: Improved atomisation

and combustion for port-fuel-injected engines,” SAE Intl, Aug. 2011. doi: 10.4271/2011-01-1890

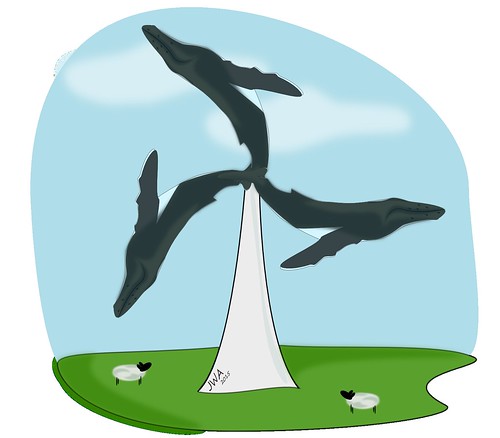

Humpback whales (Megaptera novaeangliae) are colossal; it’s a wonder how they manage to manoeuvre

their rotund bodies around the great oceans. Well, turns out the flipper of these giants goes some way

to help them complete this feat. Their flippers have bumps, better known as ‘tubercles’, which line the edge

and reduce drag by generating vortexes.

The company WhalePower has integrated these tubercles to blades which can be used to construct fans,

turbines, pumps and compressors providing greater efficiency and requiring less power to run. In the

case of wind turbines, the technology has the potential to increase operating life and functionality

at both low and high wind speeds (see here).

Among others, Northern cod (Gadus morhua) are a species of fish that endure the subzero temperatures of Arctic waters.

The fish are able to survive these extreme conditions thanks to an anti-freeze protein found in their blood.

The protein binds to ice crystals, preventing their growth and recrystallization; which occurs when the

crystals thaw and refreeze.

Ice cream is a favourite summer time treat. Its smooth texture is defined by the size and regularity

of ice crystals. When ice cream melts and refreezes the crystals change size and regularity, altering

the texture. This is a big problem for the distribution of ice cream, requiring a high energy output from

a phenomenon known as a cold chain; a temperature controlled supply chain.

A company called Unilever has helped harness the power of the fish’s anti-freeze protein. Ice cream

products can now be maintained at a high quality and distributed to remote areas without the worry of

freeze thaw cycles.

The Resurrection Plant (Selaginella lepidophylla) is aptly named for its ability to

survive almost complete desiccation. The plant inhabits deserts where, during dry conditions,

it undergoes anhydrobiosis. During this process the plant produces sugars which are thought to

protect the organism against desiccation.

Nova laboratories have produced a technology called HydRIS to produce ‘dry vaccines’. HydRIS

is based on the phenomenon of anhydrobiosis in organisms such as the resurrection plant, shrimp and nematodes. Vaccines

are dehydrated and sugars are used as a glass matrix to suspend and preserve ingredients. When water

is reintroduced to the dry vaccine, the sugar matrix dissolves allowing its use.

HydRIS boasts long term stability, aiding distribution and storage of vaccines. The technology may also

have applications for boosters, with the development of slow release vaccines.